FEATURES

For mounting heights up to 20′ (environmental separation) and 18′ (insect control).

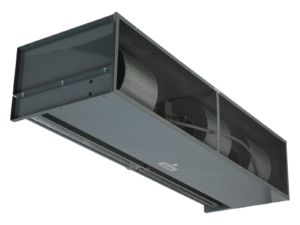

The Berner Industrial Direct Drive 20 Air Curtain has a durable, all welded construction with gray powder-coated aluminized steel exterior and removable lower section for simplified access to internal components.

Used to save energy and keep temperatures stable and flying insects out when the doors are open.

- AMCA certified ambient models only

- Recommended for shipping, receiving, garage, and railroad bay doors, and automotive manufacturing

- Engineered to perform and built to last

- Simple to install, operate, and maintain

- Made in U.S.A.

Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Available in single lengths from 5′ to 16′

Corro-Duty and Washdown Duty versions are available.

AMBIENT

- 21″ high x 32 ¼” deep

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- AMCA certified

ELECTRIC HEAT

- 21″ high x 38 ¼” deep

- Single-speed T.E.A.O. motor — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Open helical element with point suspension

- Thermal overload protection

- Galvanized steel frame

- Factory mounted heater control panel

- Alternate KW available

STEAM/HOT WATER HEAT

- 21″ high x 32 ¼” deep

- Single-speed T.E.A.O. motor — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

Coil features:

- Galvanized steel casing

- 5/8″ copper tube with .035″ wall

- Aluminum fins

- Leak tested at 450 psi

DIRECT GAS HEAT

See mechanical drawings for dimensions.

- Single-speed T.E.A.O. motor — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Factory mounted duct transition with bottom access panels

- Factory mounted modulating direct-fired heater with FM/IRI gas train

- Factory mounted wired heater control cabinet

- Steel cabinet with gray finish

- Spark ignited intermittent pilot

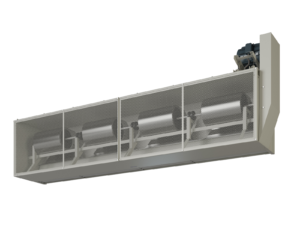

POSITIVE INDIRECT GAS HEAT

See mechanical drawings for dimensions.

- Single-speed T.E.A.O. motor — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Factory mounted duct transition with bottom access panel

- Field installed CSA Certified indirect gas heater(s):

- Aluminized steel heat exchanger (optional: stainless)

- Steel cabinet with beige finish

- Spark ignited pilot

- Power venter

- Separate 120V power supply required (optional: transformer for single point connection)

Intelliswitch

Intelliswitch for Industrial Series Air Curtains

Optional

- The Intelliswitch (digital controller) allows the user to program the air curtain to run for a set time in between door cycles, to operate on a schedule, and for air curtains with heat – to run until the thermostat set point is satisfied, and more..

- Several pre-set programs to choose from or create one tailored to the application

Berner AIR and Intelliswitch Package

Optional

- Includes BACnet-IP Support

- Program, operate & monitor Industrial Air Curtains via Berner’s mobile app

- Access reporting on energy & cost savings, door operations, and more

Accessories

This model requires an Activation Switch and a Control Panel.

Control Panels

Three Phase Control Panels:

All three phase power supplies require a three phase control panel, remote (standard) or factory mounted, and an activation switch.

Standard control panel construction: NEMA 4/12 Enclosure, Motor Contactor (factory wired), Terminal Strip, Motor Overload (one per motor), and 120V Control Transformer

Optional control panel enclosure constructions: Poly Fiberglass, Aluminum, Stainless Steel

Control Panel Accessories

- Door Switches: roller, plunger, whisker arm, or heavy duty magnetic reed style

- Hand/Off/Automatic Switches

- Start/Stop Push Button(s)

- Summer/Winter Switches

- Summer/Off/Winter Switches

- Disconnect Switch(es) – toggle disconnects based on number of power supplies required

- Remote Thermostat & Locking Cover

- Time Delay (standard in Indirect Gas Fired control panel)

Location Specific Options

Corro-Duty and Washdown Duty versions are available.

Electrical Accessories

- Indirect Gas Heater Transformer

Mechanical Accessories

- Wall support brackets

- Extension brackets, not available for electric heated air curtains

- Vertical tandem mounting bracket

- 2” Washable aluminum filters with frame, for ambient, steam & hot water heated air curtains only

Direct Gas Heat Accessories

- 10#-20# First stage gas pressure regulator – factory piped to gas train

- Ford gas train per SN 9728 with Dungs VDK

- Vertical burner box (top air inlet)

- Honeywell flame safety RM7896C1010 in lieu of Fireye

- Eaton 8411K13 remote flame failure reset switch and MED3 Board

Berner IntelliswitchTM

Digital Controller

- Takes the place of Control Packages

- Simplified pre-set programs

- Single speed motor operation

- LED clock display

- Low voltage circuit for unit activation

- Serial network connection available

- External thermostat provision

- Commercial grade components with operating range: 0° – 70°C or 32° – 158°F

- RoHS compliant

- Temperature probe (heated units only)

CONTROL PANEL is required when an Intelliswitch is used

Berner AIRTM Smart Controller & Berner App, includes BACnet

- Requires IntelliswitchTM

- Program, operate & monitor via smartphone / tablet

- BACnet-IP support

- Remote troubleshooting

- Secure: best practices for cyber security protocols followed

NOTE: Requires on-site, secure wireless connection (provided by others).