Published on the NEWS on September 8, 2014.

There has been a deluge of recent technological advancements that are creating new air curtain applications that were barely imaginable 10 years ago. Advancements range from more efficient electric heaters to manufacturing improvements that now extend lengths up to 16 feet. Air curtains that were once only custom-manufactured with explosion- and spark-proof components for hazardous industrial locations are now standardized catalog items. What was once an energy-saving device for industrial shipping doors is now embraced by retail, hotel, restaurant, and food service operators as tools for saving energy, eliminating flying insect infiltration, and increasing employee comfort.

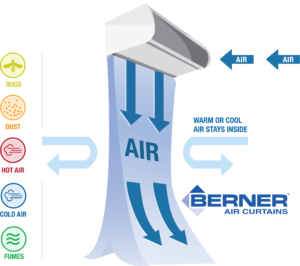

Air curtains, also known as air doors, are typically mounted inside the top of a doorway and continually discharge a steady stream of air down the threshold to separate indoor and outdoor environments. The airstream keeps unwanted cold or hot air from infiltrating an open doorway during winter or summer, respectively. The units also keep out flying insects and maintain a comfortable working environment for employees.

Airstream Efficiency

Air curtains have offered electric heating coil options for decades; however, their traditional mounting in the airstream disrupts the laminar flow that’s critical to its efficacy. Such an obstructing placement can cut airstream efficiency by up to 40 percent. Furthermore, electric heater placements in the airstream disrupt the air curtain’s all-important volume, velocity, and uniformity (VVU), which is critical for maintaining an air seal across the entire doorway for ultimate efficacy.

In addition to the discharge air, electric heaters have also been mounted at the inlet screen where air is drawn into the air curtain. While this positioning doesn’t affect the discharge, it’s less energy-efficient because the air curtain enclosure itself becomes heated. This causes up to a 5 percent heat loss radiated through the cabinet that doesn’t reach the targeted area.

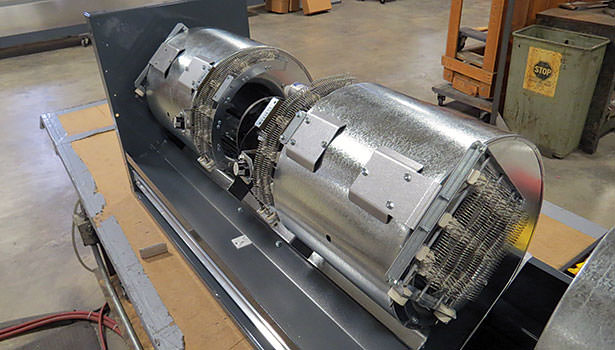

One recent invention that has corrected these inefficiencies is the Venturi-style heater, which is a hemispherical electric element array that’s strategically mounted at the air curtain blower’s inlets. Instead of an obstructive mounting in the discharge air, the element’s heat is drawn naturally into the blower via the Venturi effect, which is named for Italian 19th century physicist Giovanni Battista Venturi.

Essentially, the heating element is on the incoming side versus the discharge end of the fan/blower. The result of the Venturi effect heater is an electrically heated air curtain with no discharge obstruction; thus, the air curtain gets nearly 100 percent of the airstream’s aerodynamic potential.

Hazardous Locations

Petroleum refineries, food processing factories, pharmaceutical plants, chemical facilities, compressed natural gas (CNG) bus garages, and other hazardous locations (HL) are restricted by codes that allow only electrical components that are explosion-proof, spark-proof, and abide by other safeguards.

These special processes and environments typically create gases, dust, and other flammable or ignitable elements that can create fires or explosions generated from the spark of an electric motor, contact between ferrous metals, or arcing between electrical connections.

For years, custom-built HL-rated air curtains were available for this type of clientele, but they were custom-manufactured. Now, air curtain manufacturers are offering them as a standardized product line item, which lowers costs significantly and improves availability and lead times.

HL applications now offer large door coverage with explosion-proof motors ranging ½ to 15 hp and heavy-duty blowers to protect doorways up to 20 feet tall.

Extending Air Curtain Length

Another standardization of air curtain product lines is length. Previously, doorways wider than 12 feet typically had modular units bolted together or custom-made single-unit constructed air curtains, the latter of which carried expensive manufacturing costs. However, new technological manufacturing advancements make 16-foot lengths possible as standardized catalog items for some manufacturers. Industrial doorways commonly span widths of 12-16 feet.

The important aspect of single-unit construction is installation ease and performance. In comparison to multiple short units bolted together, single-construction air curtains typically don’t need intermediate supports, which can increase installation time and costs. Furthermore, the space between bolted units typically creates air voids. Single-construction units designed for 16-foot lengths use blower and nozzle airstream widths that cover the entire span without any interruption or turbulence. The VVU of the airstream, which can only be accomplished with a single-construction unit, is critical to air curtain performance and efficacy.

Air Curtains Substituting for Vestibules

Recent updates to the 2015 International Energy Conservation Code (IECC), which is published by the International Code Council (ICC), will now allow certified air curtains as a vestibule alternative. This is good news for commercial buildings that, in the past, were mandated to use vestibules as energy-saving airlocks.

This code change offers both a new construction and a retrofit perspective, especially for retailers. In retrofit examples, installing an air curtain and using the vestibule for merchandising space can add to a retailer’s bottom line.

The 2015 IECC code also stipulates air curtains must be tested in accordance with standard ANSI/AMCA-220 and certified by the Air Movement and Control Association Intl. Inc. (AMCA), a not-for-profit organization that tests and certifies manufacturers’ stated performance of fans, blowers, air curtains, and other air movement devices.

Food Service Applications

Walk-in cooler air curtains have been shown to surpass the energy-saving potential of alternatives, such as swinging hinged doors and strip curtains, and they produce a quick payback of less than two years, depending on the number of door cycles. While they are now predominantly appearing as options on new models from walk-in cooler manufacturers, several air curtain suppliers make retrofitting easy with a kit that includes an air curtain designed specifically for the unique size and configuration of walk-in coolers. Included in some kits are a prewired 24-V control/load center in a small enclosure and a magnetic reed on-off door switch. Once 120-V power is extended to the area, the prewired kit can be installed in as little as 15 minutes with conventional tools and basic electrical knowledge.

Besides walk-in coolers, another trend in the food service and restaurant industries is the use of drive-thru window air curtains, which are being used for a variety of purposes in many restaurant chains. They minimize both flying insect and outdoor air infiltration and protect the indoor drive-thru station employee from idling vehicle fume inhalation as well as cold air in winter climates, which are employee health and comfort issues, respectively. The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) specifically recommends a “reverse-flow fan system” at its “Teen Worker Safety in Restaurants” page.

As technological advancements move forward, even more new air curtain applications are expected to emerge. What is barely imaginable today may soon become common building construction concepts in the future.