Features

For mounting heights to 12′ (environmental separation) and 10′ (insect control).

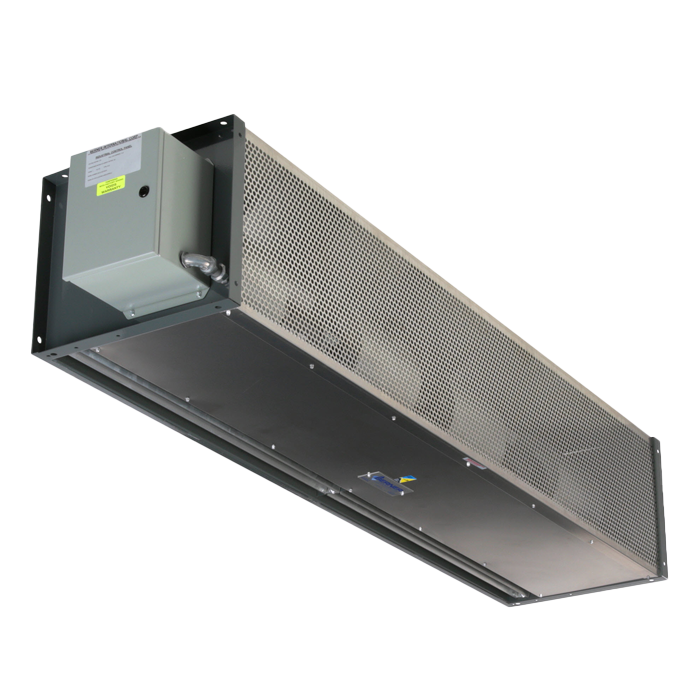

The Berner Industrial Washdown 12 Air Curtain is durable, with all-welded construction of stainless steel.

Used to save energy and keep temperatures stable and flying insects out when the doors are open.

- Specifically built for Washdown applications

- Engineered to perform and built to last

- Simple to install, operate, and maintain

- Made in U.S.A.

Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Available in single lengths from 3′ to 16′

Washdown Details

Applications:

Food processing and other applications where the unit receives washdown on a regular basis.

Unit Features:

Cabinet and internal components including fans are stainless steel. Industrial units already use waterproof wiring compartments.

Motor Features:

Single speed, 300 series stainless hardware, moisture sealant on bolt heads as well as frame and endplate, neoprene gaskets, double sealed ball bearings, built in drain plug, lip and v-ring seal on drive end, TEFC motors with ODE and DE slinger ring, stainless steel shaft F insulation, tropicalized.

Accessories

This model requires a separate Activation Switch. All air curtains using control panels require an Activation Switch to be ordered with the panel.

Control Panels

Standard location: Factory installed on left hand end plate of air curtain.

Single Phase Control Panels:

A single phase control panel is required when:

- A time delay is used

- 24 volt control is used

- When motor quantities exceed: (2) 1/2 hp @ 120V or (3) 1/2 hp @ 208-240V

An activation switch must be selected along with the panel for activation of the air curtain.

Standard control panel construction: NEMA 4/12 Enclosure, Motor Contactor (factory wired), Terminal Strip, Fusing (as required), Time Delay (as required).

Three Phase Control Panels:

All three phase power supplies require a three phase control panel and an activation switch.

Standard Control Panel Construction: NEMA 4/12 Enclosure, Motor Contactor (factory wired), Terminal Strip, Fusing (as required), and Time Delay or 120V Control Transformer (as required).