FEATURES

For mounting heights up to 16′ (environmental separation) and 14′ (insect control).

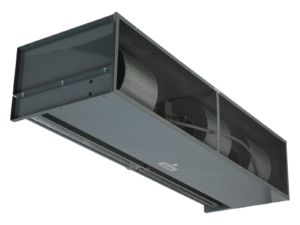

The Berner Industrial Direct Drive 16 Air Curtain has a durable, all welded construction with gray powder-coated aluminized steel exterior and a removable lower section for simplified access to internal components.

Used to save energy and keep temperatures stable and flying insects out when the doors are open.

- AMCA certified ambient models only

- Recommended for shipping, receiving, and garage doors

- Engineered to perform and built to last

- Simple to install, operate, and maintain

- Made in U.S.A.

Berner is a UL Listed panel shop, authorized to build UL listed Motor Control Panels.

Available in single lengths from 5′ to 16′

Corro-Duty and Washdown Duty versions are available.

AMBIENT

- 21″ high x 32 ¼” deep

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color, RAL colors 1000 to 9023, or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High-efficiency Pro-V Nozzle

- AMCA certified

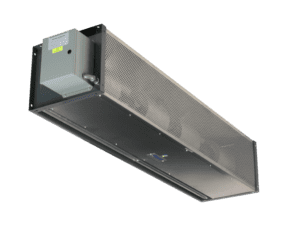

ELECTRIC HEAT

- 21″ high x 38 ¼” deep

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Open helical element with point suspension

- Thermal overload protection

- Galvanized steel frame

- Factory mounted heater control panel

- Alternate KW available

STEAM/HOT WATER HEAT

- 21″ high x 36 ¼” deep

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

Coil features:

- Galvanized steel casing

- 5/8″ copper tube with .035″ wall

- Aluminum fins

- Leak tested at 450 psi

DIRECT GAS HEAT

See mechanical drawings for dimensions.

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Factory mounted duct transition with bottom access panels

- Factory mounted modulating direct-fired heater with FM/IRI gas train

- Factory mounted wired heater control cabinet

- Steel cabinet with gray finish

- Spark ignited intermittent pilot

INDIRECT GAS HEAT

See mechanical drawings for dimensions.

- Single-speed T.E.A.O. motor(s) — direct drive

- Gray powder-coated exterior (optional: custom color or stainless)

- Split cabinet construction for fan assembly removal

- Top mounting only

- High efficiency Pro-V Nozzle

- Factory mounted duct transition with bottom access panels

- Field installed CSA Certified indirect gas heater(s):

- Aluminized steel heat exchanger (optional: stainless)

- Steel cabinet with beige finish

- Spark ignited pilot

- Power venter

- Separate 120V power supply required (optional: transformer for single point connection)

Intelliswitch

Intelliswitch for Industrial Series Air Curtains

Optional

- The Intelliswitch (digital controller) allows the user to program the air curtain to run for a set time in between door cycles, to operate on a schedule, and for air curtains with heat – to run until the thermostat set point is satisfied, and more..

- Several pre-set programs to choose from or create one tailored to the application

Berner AIR and Intelliswitch Package

Optional

- Includes BACnet-IP Support

- Program, operate & monitor Industrial Air Curtains via Berner’s mobile app

- Access reporting on energy & cost savings, door operations, and more

Accessories

This model requires an Activation Switch and a Control Panel.

Control Panels

Three Phase Control Panels:

All three phase power supplies require a three phase control panel, remote (standard) or factory mounted, and an activation switch.

Standard control panel construction: NEMA 4/12 Enclosure, Motor Contactor (factory wired), Terminal Strip, Motor Overload (one per motor), and 120V Control Transformer

Optional control panel enclosure constructions: Poly Fiberglass, Aluminum, Stainless Steel

Control Panel Accessories

- Door Switches: roller, plunger, whisker arm, or heavy duty magnetic reed style

- Hand/Off/Automatic Switches

- Start/Stop Push Button(s)

- Summer/Winter Switches

- Summer/Off/Winter Switches

- Disconnect Switch(es) – toggle disconnects based on number of power supplies required

- Remote Thermostat & Locking Cover

- Time Delay (standard in Indirect Gas Fired control panel)

Location Specific Options

Corro-Duty and Washdown Duty versions are available.

Electrical Accessories

- Indirect Gas Heater Transformer

Mechanical Accessories

- Wall support brackets

- Extension brackets, not available for electric heated air curtains

- Vertical tandem mounting bracket

- 2” Washable aluminum filters with frame, for ambient, steam & hot water heated air curtains only

Direct Gas Heat Accessories

- 10#-20# First stage gas pressure regulator – factory piped to gas train

- Ford gas train per SN 9728 with Dungs VDK

- Vertical burner box (top air inlet)

- Honeywell flame safety RM7896C1010 in lieu of Fireye

- Eaton 8411K13 remote flame failure reset switch and MED3 Board

Berner IntelliswitchTM

Digital Controller

- Takes the place of Control Packages

- Simplified pre-set programs

- Single speed motor operation

- LED clock display

- Low voltage circuit for unit activation

- Serial network connection available

- External thermostat provision

- Commercial grade components with operating range: 0° – 70°C or 32° – 158°F

- RoHS compliant

- Temperature probe (heated units only)

CONTROL PANEL is required when an Intelliswitch is used

Berner AIRTM Smart Controller & Berner App, includes BACnet

- Requires IntelliswitchTM

- Program, operate & monitor via smartphone / tablet

- BACnet-IP support

- Remote troubleshooting

- Secure: best practices for cyber security protocols followed

NOTE: Requires on-site, secure wireless connection (provided by others).